Effective removal of scale and slag from flats, plates and structural steel.

Questions? Contact one of our helpful sales managers.

Our full line service center features a 16,000-pound Wheelabrator with 8-foot by 3-foot capacity to clean all widths and lengths of metal that is covered with rust, dirt, grease, scale or burrs. The result is a material surface that is pristine and ready to accept your finishing processes, whether you are welding, machining, powder coating or painting.

Liebovich shot blasting not only removes oxidation, scale and debris from your structural shapes, it strengthens and peens the metal surface for increased resilience and durability.

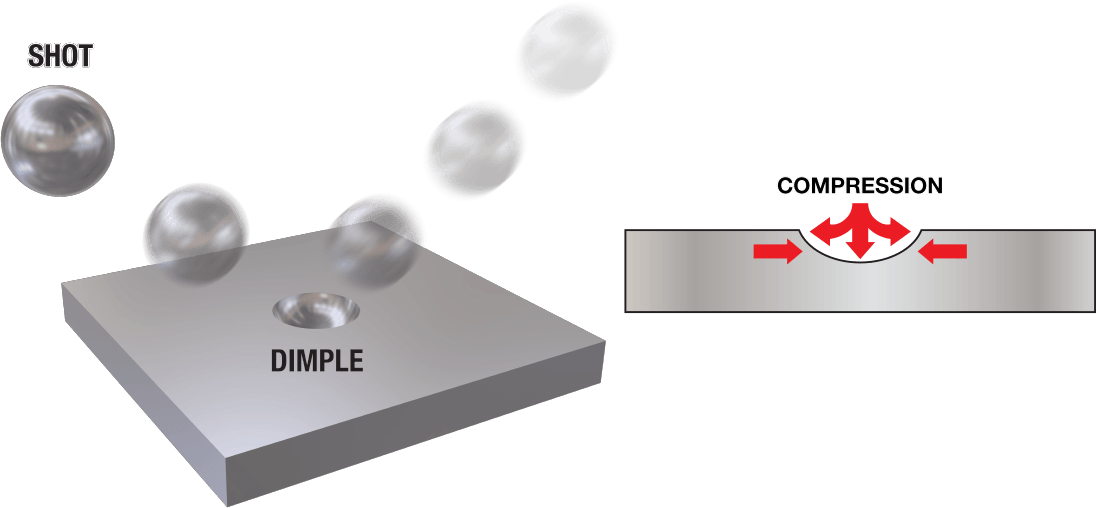

In addition to cleaning metal, shot blasting creates micro-dimpling on the surface of the metal as millions of units of shot inundate and repeatedly strike - acting like a peen hammer - to produce a uniform compression stress layer. The surface compression strengthens the overall metal, making it ready for your end-use applications.

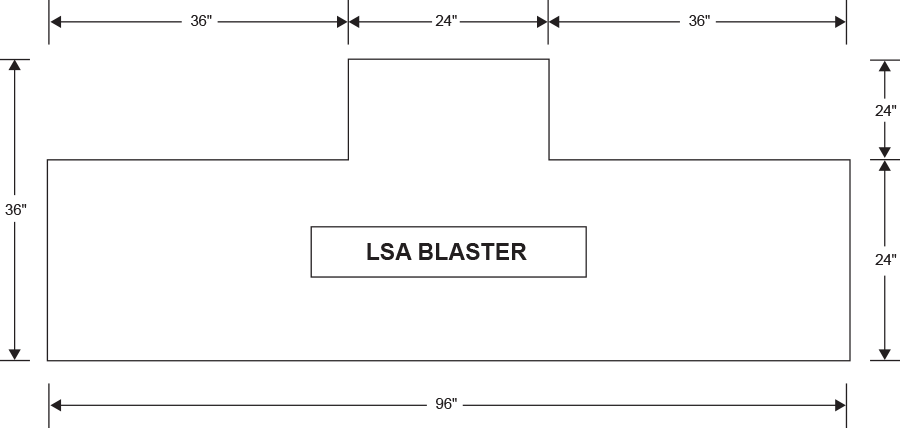

| Width (max) | 96″ |

|---|---|

| Height (max) | 36″ |

| Weight (max) | 16,336 lbs. |

Need help with an unfamiliar term? Utilize our glossary to lookup the definition.